Pipes are essential in the transportation of liquids and gases. To remain effective, they must be able to withstand the pressures and temperatures created by these substances.

Selecting the ideal pipe material is essential in this process. Not only will it affect their longevity, but also how much money you’ll have to replace them.

PVC

PVC is an amorphous thermoplastic polymer created from vinyl chloride monomer (VCM). This makes it suitable for many applications due to its characteristics of being both lightweight and strong, making it the perfect material.

Aside from its flexibility to form into various shapes, nylon offers exceptional mechanical strength and durability. As a result, it has become the go-to material for many pipe and tubing applications.

Depending on the application, plasticizers can be added to PVC to improve its various characteristics. These additives have various uses such as anti-mist, elasticity, fire retarding, flexibility, impact resistance and microbe prevention.

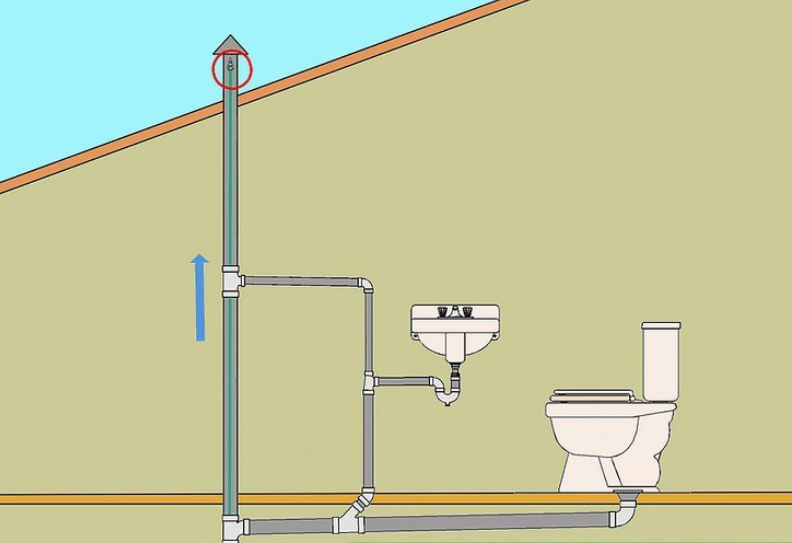

PVC is a widely-used material in the construction industry, used for flooring and wall coverings, doors/windows, sewer pipes, water transport pipes, natural gas transport pipes and more. It is lightweight yet durable enough to be easily maneuvered; has low chemical reactivity which helps it resist rusting and corrosion.

PVC piping and fittings are an excellent alternative to stainless steel when it comes to systems that could handle large volumes of water or fluid transfer. However, it should be noted that PVC piping and fittings may warp if exposed to excessive heat, so caution should be exercised during its handling.

PVC is one of the world’s most widely used materials, found in numerous everyday consumer items like raincoats, plastic bags, children’s toys, credit cards, garden hoses and door/window frames.

Vinyl chloride monomer, the primary constituent of this versatile polymer, can be obtained from oil or salt. In some countries, ethylene produced from sugar crops has also been substituted for oil-based feedstocks in PVC production.

PVC is a highly renewable product and more energy-efficient than many other thermoplastics. Furthermore, it does not degrade in the environment and can be recycled.

PVC pipe material is not only strong and long-lasting, but it’s also relatively cheap. Plus, it’s easy to work with; cuts and welds without the need for special tools.

Another advantage of PVC is that it does not corrode or rust like stainless steel does. This can be especially helpful in areas with extreme temperature swings and where pipes must remain exposed to intense sunlight or UV rays for extended periods.

PVC, despite its strength and durability, poses serious environmental hazards when manufactured, used, or disposed of. In fact, most U.S. plants that manufacture VCM (the building block of PVC) are located in Louisiana or Texas.

Although these plants may not be situated in the most environmentally friendly places, they still release large amounts of toxic chemicals into the environment during their operations. This poses a serious risk to nearby residents and animals, especially those that depend on drinking water supplies for survival.

PVC is a non-biodegradable material that has the potential to remain in the environment for up to 40 years, releasing toxic chemicals into air and water that have an adverse effect on human health and the environment. While PVC may be strong, durable and cost effective, it’s time to move away from less eco-friendly options.